In the hushed workshops where jade meets artistry, a quiet revolution is unfolding. For centuries, the carving of this revered stone has been a dance with danger, a high-stakes endeavor where a master's lifetime of skill could be undone by a single, imperceptible miscalculation. The inherent fragility and immense value of fine jade demand a process of near-surgical precision, a requirement that traditional tools, for all their history, could never fully guarantee. The quest has always been for a method that could marry the brute force needed to shape the stone with the delicate touch required to preserve its soul. That method has now arrived, not with a roar, but with the whisper-thin whir of diamond wire.

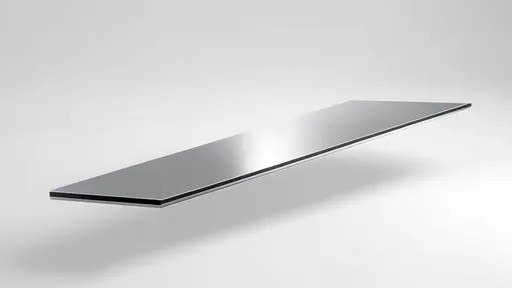

The core of this technological leap lies in the wire itself. Unlike the rigid blades and abrasive wheels of the past, diamond wire cutting employs a flexible, multi-strand steel cable, often no thicker than a human hair. This cable is impregnated with microscopic, industrial-grade diamond particles, the hardest natural material on earth, bonded to the wire with extreme precision. As the wire is fed through the jade at high speeds, these diamond micro-teeth become an army of infinitesimal sculptors, each removing a minuscule amount of material with every pass. The cut is not a tear or a fracture but a controlled, atom-by-atom erosion, guided by computer numerical control (CNC) to follow paths measured in microns.

This shift from macro to micro is what fundamentally changes the game. Traditional saws and blades operate through forceful, broad-contact abrasion or impact. They transfer significant vibration and shock loads into the jade, creating micro-fractures that can spiderweb deep beneath the surface, unseen to the naked eye but fatally compromising the structural integrity and future stability of the piece. Diamond wire, by contrast, exerts almost negligible lateral pressure. The "kerf," or width of the cut, is exceptionally narrow, minimizing material loss—a crucial factor when working with priceless gemstones. Most importantly, the nature of the cut is so clean and localized that it leaves the surrounding material completely untouched, truly "unharmed."

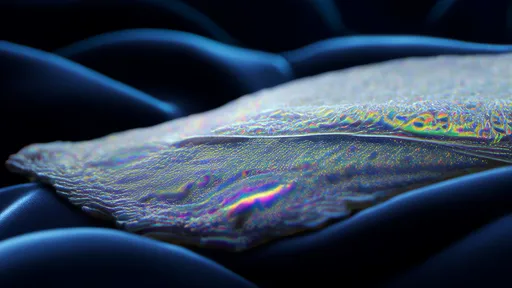

The practical applications of this technology within a jade carving atelier are transformative. Consider the painstaking process of piercing—creating intricate openwork and deep undercuts within a sculpture. Previously, this required drills and tiny saws that could easily shatter delicate arches of jade or leave behind rough, stressed internal surfaces. With diamond wire, an artist can thread the filament through a pre-drilled pilot hole and carve out complex internal geometries from within, all while the outer surface of the block remains perfectly intact and supportive. It allows for the creation of previously impossible forms: impossibly thin, flowing ribbons of jade; complex interlocking chains carved from a single block; and deep, intricate cavities that reveal inner layers of color without risking a collapse.

Beyond enabling new artistic frontiers, diamond wire cutting is a powerful tool for conservation and restoration. The world's museums and private collections hold countless jade artifacts that have sustained damage over centuries. Repairing these pieces often involves separating broken sections to insert adhesives or reinforcements. The precision of a diamond wire allows conservators to make a clean, new cut exactly where needed—perhaps to remove a old, failed repair—without risking further damage to the original, ancient material. It provides a level of control that is the closest thing to a restorer's scalpel for stone.

However, the technology is not a magic wand that replaces the artist. It is, instead, the ultimate enabler. The CNC machines that guide the wire are programmed with digital models, which are themselves the products of the carver's vision and skill. The artist must still possess a deep understanding of jade's nature—its grain, its subtle color variations, and its hidden flaws. The machine executes with cold precision, but the human spirit provides the intent. The diamond wire becomes an extension of the artist's hand, granting them the ability to execute their most ambitious designs with a confidence that was once unthinkable.

As this technology continues to evolve, becoming more accessible and refined, its impact on the art of jade carving will only deepen. It represents a perfect synergy between ancient tradition and cutting-edge innovation, where the reverence for the material is matched by the precision of the tools used to shape it. In the silent hum of the diamond wire, we hear the future of an ancient craft—a future where the beauty of jade can be revealed not just with skill, but with absolute respect, leaving every untouched millimeter truly injury-free, unharmed to the very last hair.

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025